Climb Milling vs. Conventional Milling

There are two distinct ways to cut materials when CNC milling: Conventional Milling (Up) and Climb Milling (Down). The difference between these two techniques is the relationship of the rotation of the cutter to the direction of feed. In Conventional Milling, the cutter rotates against the direction of the feed. During Climb Milling, the cutter rotates with the feed.

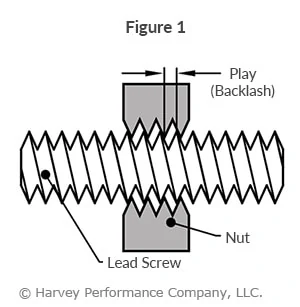

Conventional Milling is the traditional approach when cutting because the backlash, or the play between the lead screw and the nut in the machine table, is eliminated as seen in Figure 1 below. Recently, however, Climb Milling has been recognized as the preferred way to approach a workpiece since most machines today compensate for backlash or have a backlash eliminator.

Key Conventional and Climb Milling Properties:

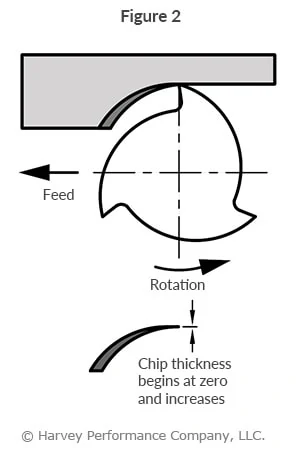

Conventional Milling (Figure 2)

As previously stated, traditionally conventional milling has been the common choice for most machinists. This is where the cutting edge of the tool is actually rotating away from the direction of the feed. An example of this is seen in Figure 2 below. Until recently, this has been the common choice due to backlash however, the rise of climb milling has caused machinists or machines to adapt and compensate for this issue.

That is not to say there aren’t benefits to climb milling. For example, this strategy offers a machinist more control and less vibration than its climb milling counterpart. Similarly, for materials that traditionally chatter or tear, conventional milling would be the proper strategy to choose. On the other hand, here are some reasons why it might be most beneficial to adopt a climb milling strategy:

- Chip width starts from zero and increases which causes more heat to diffuse into the workpiece and produces work hardening

- Tool rubs more at the beginning of the cut causing faster tool wear and decreases tool life

- Chips are carried upward by the tooth and fall in front of cutter creating a marred finish and re-cutting of chips

- Upwards forces created in horizontal milling* tend to lift the workpiece, more intricate and expansive work holdings are needed to lessen the lift created*

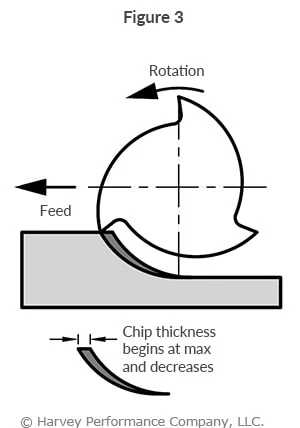

Climb Milling (Figure 3)

As machinists are always trying to find ways to increase efficiency and tool life, climb milling has gotten a lot of recent traction in the space. Less heat is generated within the tool, and friction is more easily mitigated. These two alone lead to longer tool life, allowing for more parts completed per tool, lowering a shops bottom line. Also, climb milling can lead to a better surface finish due to how the chips are formed at the cutting edge.

With more modern machines now compensating for backlash or utilize backlash eliminators, it has become a much easier strategy to adopt within shops. While we went over some reasons why climb milling is not an effective strategy above, here are some reasons why a machinist may want to explore climb milling:

- Chip width starts from maximum and decreases so heat generated will more likely transfer to the chip

- Creates cleaner shear plane which causes the tool to rub less and increases tool life

- Chips are removed behind the cutter which reduces the chance of chip recutting

- Downwards forces in horizontal milling is created that helps hold the workpiece down, less complex work holdings are need when coupled with these forces

- Horizontal milling is when the center line of the tool is parallel to the work piece

When to Choose Conventional or Climb Milling

Climb Milling is generally the best way to machine parts today since it reduces the load from the cutting edge, leaves a better surface finish, and improves tool life. During Conventional Milling, the cutter tends to dig into the workpiece and may cause the part to be cut out of tolerance.

However, though Climb Milling is often the current preferred way to machine parts, there are times when Conventional Milling is the necessary milling style. One such example is if your machine does not counteract backlash. In this case, Conventional Milling should be implemented. Without accounting for backlash, breakage can occur due to the forces within the machine during tool engagement.

In addition, conventional milling should also be utilized on casting, forgings or when the part is case hardened. This is due to the cut beginning under the surface of the material, where it will gradually build a chip. Climb milling into these materials will see maximum chip thickness on engagement, which could lead to premature failure of the cutting edge due to the forces generated.