Main Differences Between Engravers & Marking Cutters

Understanding the Distinctions

While similar on the surface, Half-round Engraving Cutters and Marking Cutters are actually very different. Both tools are unique in the geometries they possess, the benefits they offer, and the specific purposes they’re used for. Below are the key differences that all machinists must know, as the engraving on a part is often a critical step in the machining process.

Engravers & Marking Cutters Serve Different Purposes

All Marking Cutters are Engraving Cutters, but not all Engraving Cutters are Marking Cutters. This is because Marking Cutters are a “type” of engraving tool. By virtue of their sturdier geometry, these tools are suited for applications requiring repetition such as the engraving of serial numbers onto parts. Harvey Tool has been able to customize specific tool geometries for ferrous and non-ferrous applications, offering Marking Cutters for material specific purposes.

Engraving Cutters, on the other hand, are meant for finer detailed applications that require intricate designs such as engraving a wedding band or a complex brand design.

These Tools Have Unique Geometry Features

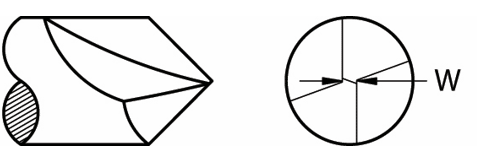

Historically, Engraving Cutters have been made as a half round style tool. This tool allows for a true point, which is better for fine detail, but can easily break if not run correctly. Because of this, these tools have performed well in softer materials such as aluminum and wood, especially for jobs that require an artistic engraving with fine detail.

Marking cutters are not as widely seen throughout the industry, however. These tools hold up in harder-to-machine materials exceedingly well. Marking Cutters are a form of Engraving Cutter that contain 2 flutes and a web at the tip, meaning that the tool has a stronger tip and is less susceptible to breakage.

While these tools do not contain a true point (due to their web), they do feature shear flutes for better cutting action and the ability to evacuate chips easier when compared to a half-round engraver.

Harvey Tool Product Offering

Harvey Tool offers a wide variety of both Engraving Cutters and Marking Cutters. Choose from a selection of pointed, double-ended, tip radius, and tipped-off Engraving Cutter styles in 15 included angles ranging from 10° to 120°.

Marking Cutters are fully stocked in tip radius or tipped-off options, and are designed specifically for either ferrous or non-ferrous materials. They are are offered in included angles from 20° to 120°.

While Engraving Cutters are offered uncoated or in AlTiN, AlTiN Nano, or Amorphous Diamond coatings, Marking Cutters are fully stocked in uncoated, AlTiN, or TiB2 coated styles.

Add Fine Details to Your Parts With Harvey Tool’s Expansive Selection of Marking Cutters

Choosing the Right Tool

While both Engraving Cutters and Marking Cutters can accomplish similar tasks, each tool has its own advantages and purpose. Selecting the correct tool is based largely on preference and applicability to the job at hand. Factors that could impact your selection would be final Depth of Cut, Width of Cut, the angle needing to be achieved, and the desired detail of the engraving.

Great article about engraving Cutters and Marking Cutters

Yes indeed, I learned alot about engraving blades here.

Looking for customised solutions for engraving cutter.

Hi Shrutesh,

Thanks for reaching out. Please contact Harvey Tool’s technical support team at 800-645-5609 and someone would be happy to help you!

Hello there! Excellent take on engravers and marking cutters. I particularly liked the bit about the tools having unique geometry features particularly the part where you expounded on shear flutes that offer better cutting action and the ability to evacuate chips easier as compared to a half-round engraver. I’ll be getting an engraved stale sign from this maker soon” https://www.countyhousesigns.co.uk, and I want to understand everything about its manufacturing and ensure to get the best one.

Great tips,laser marking discolors the surface of the material, while laser etching and engraving actually removes a portion of the surface area as it marks.

Thanks for explaining that choosing the correct tool is based on preference applicability. My brother needs to have some custom signs engraved for his small business. I’ll share this article with my brother as he determines the best way to create the engraved signs.

Thanks for pointing out that engraving materials are often used for softer materials such as wood and aluminum. I just needed to know the process I might need for the wood souvenirs that I plan to have for our wedding. We would have our dates and names imprinted there once we find a professional engraver we can trust.

Many thanks. keep up the good work

Great article, sorry I took so long to read it!! Is it possible to order directly from Harvey? The closest distributor is 2.5 hours away and doesn’t stock the parallel engraving cutters I need.

Thanks!

Hello George,

We currently do not sell direct. You can order the parallel engravers through a different distributor and have them drop ship the package to your location.

Well this is awesome post and written very well. Your point of view is very good.

Great Article well written thank you for providing this information keep writing