The Geometries and Purposes of a Slitting Saw

When a machinist needs to cut material significantly deeper than wide, a Slitting Saw is an ideal choice to get the job done. These are unique due to their composition and rigidity, which allows it to hold up in a variety of both straightforward and tricky to machine materials.

What is a Slitting Saw?

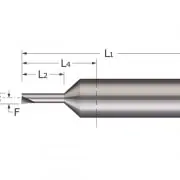

A Slitting Saw is a flat (with or without a dish), circular-shaped tool that has a hole in the middle and teeth on the outer diameter. Used in conjunction with an arbor, this tool is intended for machining purposes that require a large amount of material to be removed within a small diameter, such as slotting or cutoff applications.

Other names include (but are not limited to) Slitting Cutters, Slotting Cutters, Jewelers Saws, and Slitting Knives. Both Jewelers Saws and Slitting Knives are particular types of saws. Jewelers Saws have a high tooth count enabling them to cut tiny, precise features, and Slitting Knives have no teeth at all. On Jewelers Saws, the tooth counts are generally much higher than other types of saws in order to make the cuts as accurate as possible.

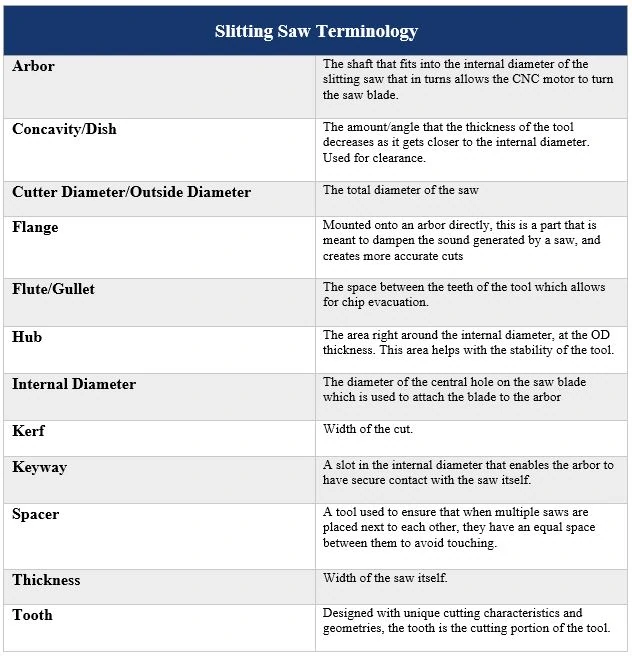

Key Terminology

Why Use a Slitting Saw?

These saws are designed for cutting into both ferrous and non-ferrous materials, and by utilizing their unique shape and geometries, they can cut thin slot type features on parts more efficiently than any other machining tool. Non-Ferrous slitting saws have fewer teeth, allowing for aggressively deep depths of cut.

Common Applications:

- Separating Two Pieces of Material

- If an application calls for cutting a piece of material, such as a rod, in half, then a slitting saw will work well to cut the pieces apart while increasing efficiency.

- Undercutting Applications

- Saws can perform undercutting applications if mounted correctly, which can eliminate the need to remount the workpiece completely.

- Slotting into Material

- Capable of creating thin slots with a significant depth of cut, Slitting Saws can be just the right tool for the job!

When Not to Use a Slitting Saw

While it may look similar to a stainless steel circular saw blade from a hardware store, this tool should never be used with construction tools such as a table or circular saw. Brittle saw blades will shatter when used on manual machines, and can cause injury when not used on the proper set up.

In Conclusion

Slitting Saws can be beneficial to a wide variety of machining processes, and it is vital to understand their geometries and purpose before attempting to utilize them in the shop. They are a great tool to have in the shop and can assist with getting jobs done as quickly and efficiently as possible.

I’m curious to know what kind of depth of cuts this can take in one shot? Where is the point to where the saw could load up with chips if they can’t get out?

Hi Chris,

Thanks for the question! Harvey Tool Slitting Saws can take up to 5x / 500% thickness. Please be aware of the size of the washers on your arbor, however. If they are large enough, they may impede the radial amount these tools are able to cut. More information can be found here: http://harveytool.com/secure/Content/Documents/SF_SAA0100.pdf

Please contact our tech team at 800-645-5609 if you have any questions!

Thanks

WOW, amazing article. I used Jigsaw tool because it’s lightweight and portable tool.

I never knew that the high tooth count on jeweler saws makes them able to make more precise and sharper cuts. My husband loves to work with his hands on projects for fun, and I have been looking for a Christmas present for him. I think that some diamond blades would be a really exciting gift for him to jumpstart his next project.

Thanks, Sabrina! Feel free to give us a call at 800-645-5609 if we can help in any way!

Out of curiosity, what kind of finish will the slitting saws leave on the material that it cuts? And what tolerances will it cut to when set up properly? I’m working on a project and need to cut a .150″ slit in the end of a of some w1 round stock and need the finish to be better than attempting to use an end mill as it will be the pivot point for some chain.

Thanks!

Hey Zach,

Due to the amount or variables that go into machining we can’t truly determine the finish left by the slitting saw. We would say using a finishing tool after the slitting saw will provide you the best finish.